Reverse Engineering – What do you do with your scan data?

Useful CAD from heavy point clouds

Compared to just a few years ago when I came to OR3D, when scan data was a relatively heavy and clunky data type, raw scan data today is becoming increasingly usable and is compatible with more software than ever before. This, combined with a greater awareness; BBC’s Invisible Cities has put laser scanning right in the centre of the public eye, is driving the industry and the technology forward at an incredible rate. In fact, just keeping up with all of the new iterations of software and hardware is a struggle.

So although point clouds are becoming more useful, there is still an undeniable need for CAD models. Your clients expect useful, parametric CAD files. If they can have those in a native file format with full history tree, then so much the better. Companies who are new to laser scanning tend to have very high expectations. Everyone seems to expect a CAD model to appear in front of their eyes, seconds after putting the scanner down. The concept of scan to CAD or reverse engineering, in the public eye at least, is still in its infancy.

Although there have been attempts at getting parametric models to simply appear, nothing, at the moment at least, can compete with a manually, fully reverse engineered, CAD model. Anyone can produce a point cloud or a mesh, some can produce an auto-surface but from my experience, a parametric CAD model is what everybody actually wants and needs.

Getting people or companies to explore new technology can not be forced. People are far more accepting to adapt an existing workflow rather than change it all together. Companies are desperately trying to tick the “innovation” check box but employees tend to be less than willing to change their ways to do this. Software that is able to integrate rather than replace is key here. Employees have spent a long time honing their skills in software packages such as Solidworks and Inventor and are not motivated to start that learning process again.

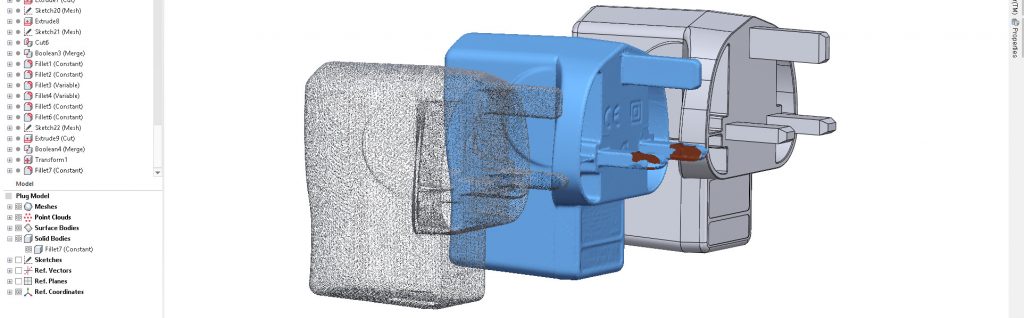

Geomagic Design X, for reverse engineering, in my opinion should be the answer to the question “What do you do with your scan data?”. The software boasts the ultimate scan to CAD solution, offering many different workflows. This allows users to work in ways familiar to them. Once the reverse engineering is complete they can then use the “Live Transfer” tool to transfer their creation into their native CAD package. Design X truly integrates, rather than replaces.

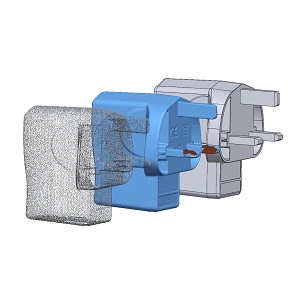

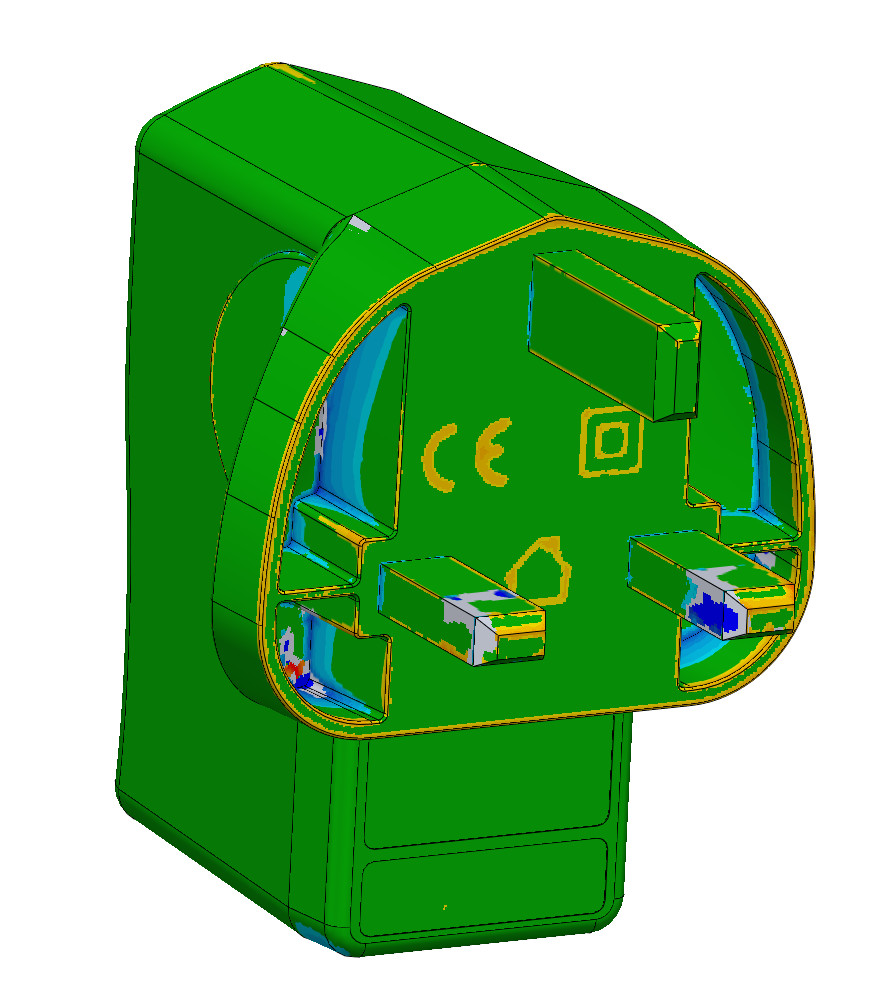

The video below demonstrates some of the capability of Design X while reverse engineering a USB charger from scan through to CAD model.

Robert Wells,

Applications Engineer